Digitalization

Industry 4.0

Digital transition

To improve productivity and efficiency

Our company has completed the 4.0 transition by investing heavily in training, human resources and first-class capital goods.

We fully integrate digital tools and technology into all operations, in order to increase productivity, create a better customer experience, and improve the efficiency and effectiveness of business processes.

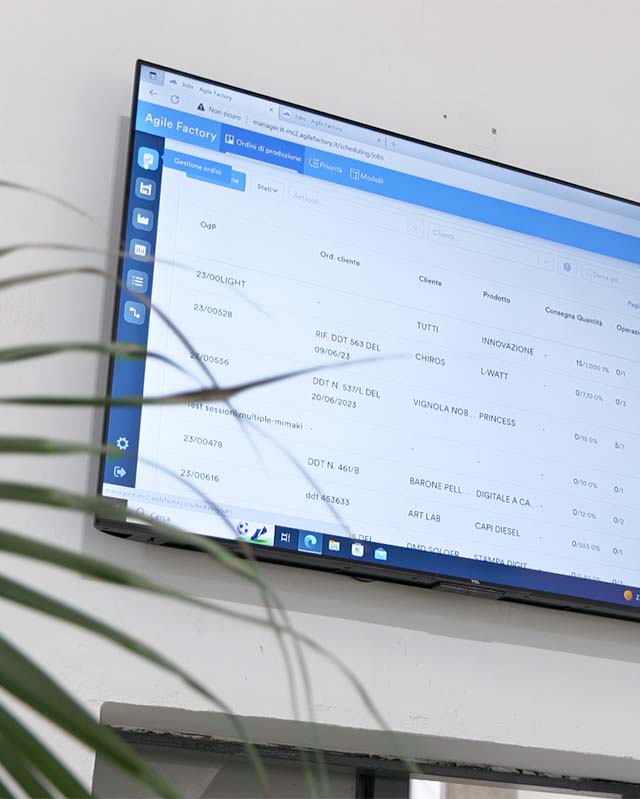

All departments and machines are interconnected thanks to an advanced MES system, “Agile Factory”, completely customized according to the company’s needs. An integration that allows precise workflow monitoring, facilitates traceability and traceability, allowing you not only to monitor costs and yields efficiently, but also to optimize production and reduce waste.

The revolution of Mc quadro

Real-time traceability

The MES system, in addition to optimizing the production process by making it more efficient and flexible, also offers the distinctive feature of transparency and direct customer involvement.

Our company provides its customers with an exclusive link, through which it is possible to track the status of the commissioned work in real time. This direct and constant access to the production situation not only guarantees complete visibility, but also establishes a relationship of trust and openness, laying the foundations for a long-lasting and satisfactory collaboration.

The decision to integrate and make available this functionality testifies to the importance we place not only on manufacturing excellence, but also on customer satisfaction and engagement.